Zhejiang Sugar Ene Technology Co., Ltd. has been committed to the design and development of new bio-based furan materials, and has formed a stable production chain to provide high-quality new material products for various customers. In September this year, the company's flagship product 5-Hydroxymethylfurfural (HMF), the key platform compound 2,5-furandicarboxylic acid (FDCA), which is a key platform compound 2,5-furandicarboxylic acid (FDCA) by oxidation, was completed. focus on.

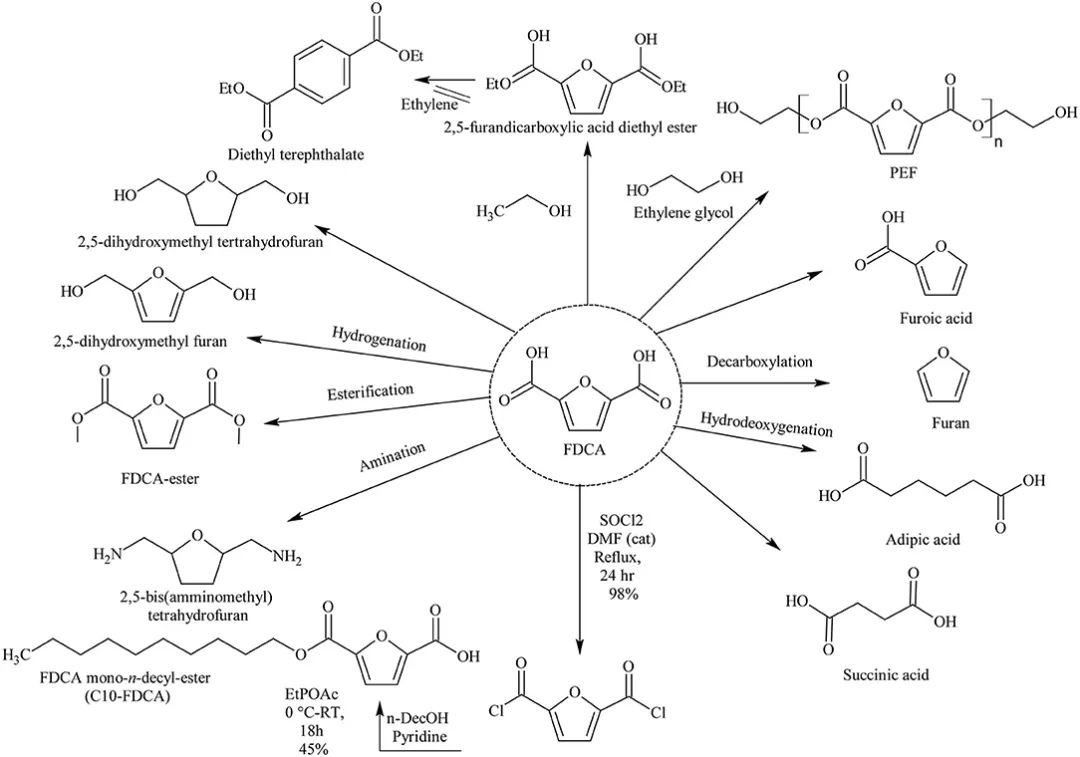

2,5-Furandicarboxylic acid (FDCA), a representative of aromatic bio-based platform chemicals, is known as the "sleeping giant" due to its huge market potential. In recent years, FDCA has been applied in many fields. According to the research in academia and the feedback from our customers - in terms of pharmacology, it has been proved that its diethyl ester has a strong anesthetic effect similar to that of cocaine. Dicalcium 2,5-furandicarboxylate was shown to inhibit the growth of Bacillus megaterium. Screening studies of FDCA-derived anilines showed that they have important antibacterial effects. The diacid itself is a strong complexing agent, chelating the following ions: Ca 2+, Cu 2+ and Pb 2+; can be used medicinally to remove kidney stones, HMF is passed through FDCA in mammals including humans Metabolism, a very diluted solution of FDCA in tetrahydrofuran, can be used to prepare artificial veins for transplantation.

FDCA also benefits from industry as a stable compound, as most polycarboxylic acids can be used as ingredients in fireproof foams. This foam helps to extinguish fires caused by polar and non-polar solvents in a short period of time.

FDCA has great potential as a substitute for terephthalic acid, its downstream product polyethylene 2,5-furandicarboxylate (PEF), compared with polyethylene terephthalate (PET), Not only is it sustainable and recyclable, but also has obvious advantages in performance such as heat resistance, mechanical strength, and gas barrier properties. For example, through the reaction of FDCA with diamines, or through the conversion of FDCA into polyamides, these concepts can be extended to the production of new nylons, hopefully fully aromatic temperature-resistant nylons.

Image illustrating the versatility and range of FDCA derivatives

In addition, compared with PET, FDCA-based polyester is not only 100% bio-based, but also has the advantages of air tightness, thermoplasticity, and better stretchability. It is also a completely recyclable and renewable high-performance plastic. The petroleum-based polyester PET has more excellent physical-mechanical properties and huge environmental benefits. It has passed the EU food safety certification and is the main alternative to the EU "plastic ban" in 2023.

Bio-based materials belong to both the technology industry and the low-carbon industry. The Ministry of Industry and Information Technology will also vigorously develop high-end degradable materials as the key task of the "14th Five-Year Plan", and promote biodegradable plastics enterprises to carry out technological innovation, transformation of scientific and technological achievements and product application. According to estimates by relevant state agencies, if China wants to achieve its carbon neutrality goal in 2060, it may need to invest 136 trillion yuan. It is foreseeable that bio-based materials and degradable plastics will usher in major development opportunities.

Based on its existing advantages, Tangneng Technology has completed the production and preparation of PEF kilograms in October this year. This move will seize the opportunities brought by economic and social development under my country's "dual carbon" goal and continue to promote a new round of industrial renewal.

Our company will also further explore the economic value of the "dual carbon" goal, open up new production routes, and provide customers with high-quality new material products in the first time in the future.